Meet Anders Gingsjö, PhD, CTO at Osstell

Jul 4, 2017

Chief Technology Officer at Osstell

Could you please introduce yourself to our readers and tell us a little bit about your background?

I started my university education at Chalmers University Technology here in Gothenburg with a M.Sc. in computer engineering and Health Science. Continued as a Ph.D. student in the Hearing Aid group led by Professor Bo Håkansson. The resulting Ph.D. Thesis, in 1997, was in the field of Hearing Aid Technology, i.e. signal processing, and electronics in health science. The thesis “Transient Noise and its Reduction in Hearing Aids” dealt with the problem that sound from hearing aids commonly are perceived as harsh and unpleasant, resulting in a large portion of hearing aids not being used.

As some of you might know, Professor Håkansson is the father of the Bone Anchored Hearing Aid (BAHA). The BAHA utilizes a small titanium implant placed in the mastoid part of the temporal bone. The interesting thing with it all, is that the working principle is very close to a SmartPeg in a dental implant in that vibrations in both cases are fed into implant/bone interface. And yes, Osstell has SmartPegs to test Hearing Aid implants too…

My expertise is towards an architectural medical device area, specifically in electronics, but from an engineering point of view, it all becomes mathematical models in which the functionality of a ‘device’ can be described and verified before it is physically built. What I’m saying is, that a person skilled in electrical circuit theory easily can understand and model the mechanical properties of a vibrating SmartPeg, as the same set of differential equations can be used to describe both systems.

I will end the technical story with a question – have you ever listened to a SmartPeg by means of bone conduction?

If not, put a SmartPeg with its stem between your front teeth, keep it there with a little pressure and try to measure the ISQ with a probe. The experience is even more pronounced if you have hearing protections on.

Can you tell us a bit more about what you have worked with before starting at Osstell?

Professionally, I have worked with medical devices since 1998, typically with Quality Assurance (QA), as senior system architect and also as software and hardware designer. In the beginning with a distributed EEG-analysis system. In 2005 in a small team succeeding with a FDA PMA for the STAN fetal ECG monitor. I’m the single inventor on two patents for a single use fetal ECG electrode system. Since 2010 until late 2016, I have been working as senior system architect designing X-ray QA instrument, used for conventional X-ray as well as cone beam CT used in dental practice. A unique system with a variety of X-ray detectors was developed during these years, so successful that the entire company was bought by FLUKE Biomedical.

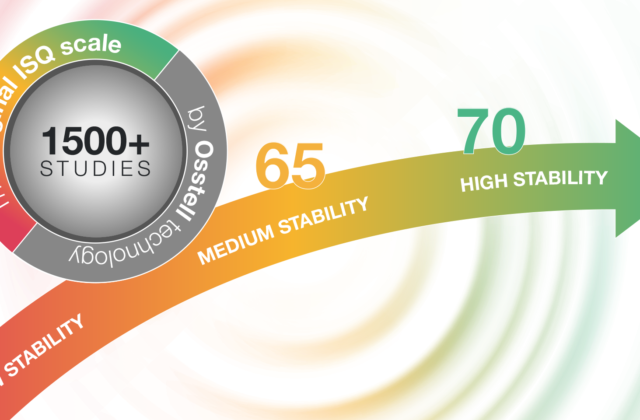

“Osstell may have the potential to half the failure rate, that’s not bad at all!”

Why did you choose to work at Osstell?

I chose to work at Osstell, partly since I worked with some of the people before, and partly since the products have great potential.

The product is simple and easy to use, and this is essential for commercial success. Before I started, I asked a dentist friend of mine about Osstell ISQ, he hadn’t heard about it, but the specialist oral surgeon who is assisting him one day a month had used it for clinical research. Then I asked him about failures, out of five failures, one was due to osteoporosis, two from early loading, and two for unknown reasons. My conclusion from his reply is that, Osstell may have the potential to half the failure rate, that’s not bad at all!

Then, when I read the interview with Dr. William Martin, he’s actually touching the subject with a similar line of reasoning.

Yes I am a believer in ISQ too…

What is your role and what are your main topics here at Osstell?

The role as CTO in Osstell AB is especially interesting since the company is quite small, hence the job description becomes extensive with many roles to fill. As a technical and regulatory expert in the field of medical devices, one the most important responsibilities is to make sure new and existing products are working well for our customers.

What inspires you?

My philosophy is to try keeping things simple. If something cannot be made simple and beautiful, one is either off track or is not thinking straight.

It is also impossible to get a large customer base to use a product that is too complicated, so there are really no alternatives to this philosophy.

What are your personal interests?

When I’m not working I like to go cross country skiing in the winter, and enjoy bicycling on small, car-free and scenic roads in the summer in order to somewhat counter act too many office hours. I need to be in decent shape to not drop behind by my brother while cycling, as he is a former dual Olympic swimmer who never really stopped training. When the weather is fine, the very light summer evenings in Sweden are also perfect for some relaxed fishing.